Custom Brushed Hard Aluminum Anodized Printing Metal Name Plate

Product Description

| Product Name: | Custom Brushed Hard Aluminum Anodized Printing Metal Name Plate |

| Material : | Aluminum,stainless steel, Brass, copper, Bronze, iron etc. |

| Design : | Custom design, refer to final design artwork |

| Size & Color: | Customized |

| Shape : | Any shape for your selection or customized. |

| Artwork format: | Usually, PDF, AI, PSD, CDR, IGS etc file |

| MOQ : | Usually, Our MOQ is 500 pieces. |

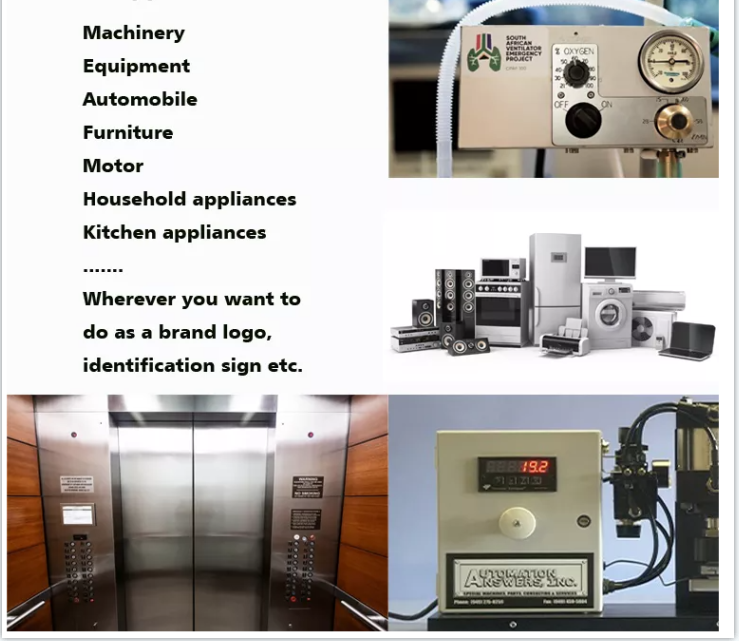

| Application: | Furniture, Machinery, equipment, elevator, motor, car, bike, household&Kitchen appliances, Gift box, Audio, industry products etc. |

| Sample time : | Usually, 5-7 working days. |

| Mass order time: | Usually, 10-15 working days. It depends on the quantity. |

| Finishes: | Engraving, Anodizing, painting, lacquering, brushing, diamond cutting, polishing, electroplating, enamel, printing, etching, die-casting, laser engraving, stamping, Hydraulic pressing etc. |

| Payment term: | Usually, our payment is T/T, Paypal, Trade Assurance order through Alibaba. |

What’s a Aluminum Name plate Used For?

Aluminum name plate are used for a variety of purposes ranging from identification to safety warnings, and many of the nameplates available are customized with any image, design, or information. That means you can decide exactly how you want nameplates to work in your business.

. Instruction

Nameplates can include more than identification content. They could include instructions for operation. For example, equipment nameplates on a copy machine might provide graphics about how to clear a paper jam, or plates on manufacturing equipment could identify the critical operating buttons and levers with brief definitions of what they do.

. Safety

Metal nameplates could step beyond instruction to help increase safety. Warning signs about hazardous chemicals or dangerous equipment, information about the maximum load or a reminder to wear a hard hat beyond a certain door are all examples of how metal plates can help support safety.

.Branding

Appliance, automobile, and electronics manufacturers are just some of the companies that use metal nameplates for branding on their products. Putting a plate with your company logo or company name in a prominent location on a product helps increase brand awareness and reputation.

Application

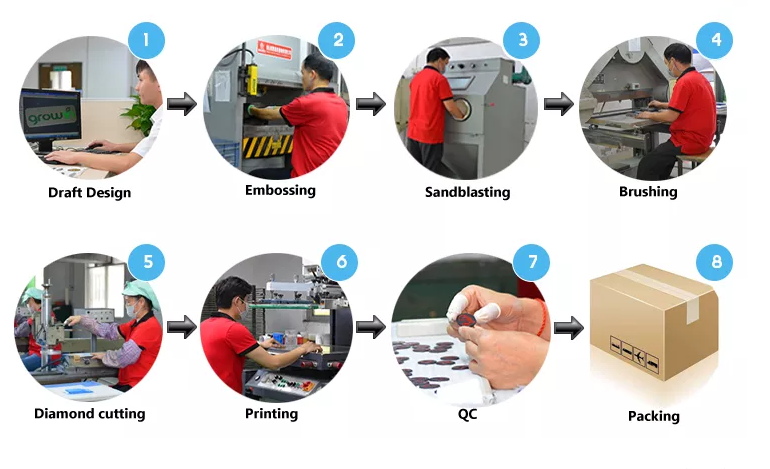

Production process

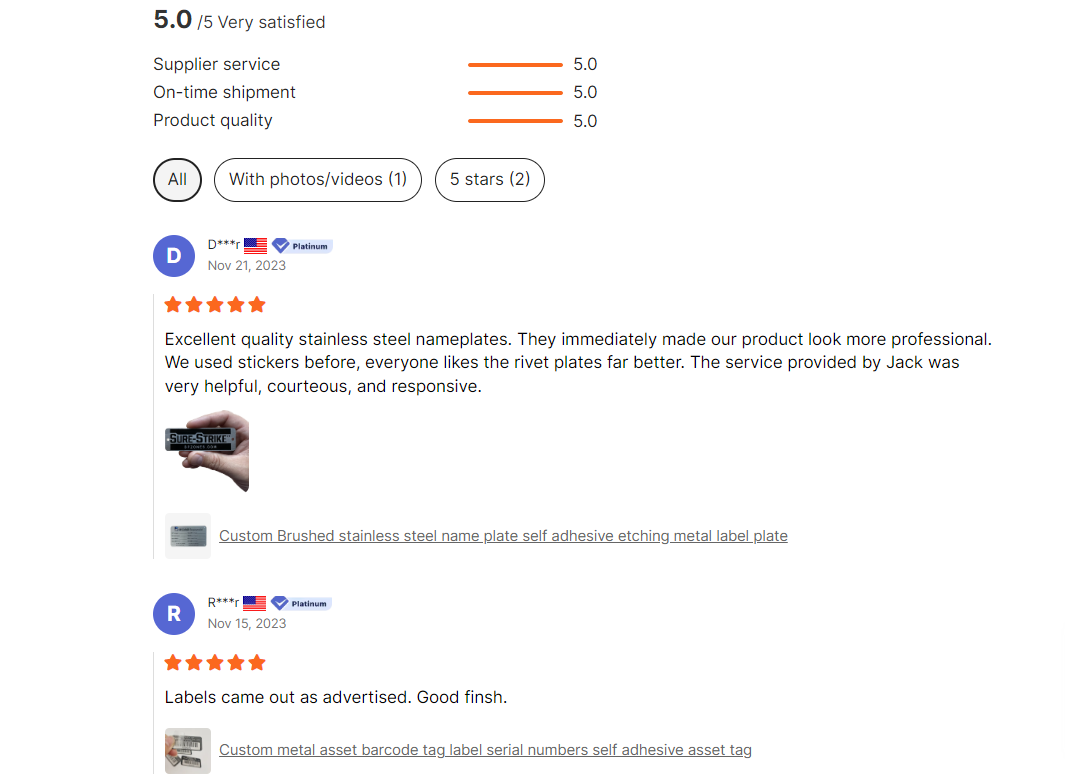

Customer Evaluation

FAQ

Q: What’s the product finishes you can offer?

A: Usually, we can make many finishes like brushing, anodizing, sandblasting, electroplating, painting, etching etc.

Q: What’s your lead-time?

A: Usually, 5-7 working days for samples, 10-15 working days for mass production.

Q: How do I pay for my order?

A: Bank transfer, Paypal, Alibaba trade Assurance order.

Q: Is your company a manufacture or trader?

A: 100% manufacture located in Dongguan, China with 18 years more industry experience.

Q: Can we get some samples?

A: Yes, you can get actual samples in our stock for free.

Q: How Can I get a quotation?

A: We will quote you exactly based on your information such as material, thickness, design drawing, size, quantity, specification etc.

Q: What’s the packing for your products?

A: Usually, PP bag, foam+ Carton, or according to customer’s packing instructions.

Q: What are different payment methods?

A: Usually, T/T , Paypal, Credit card, Western union etc.

Q: What’s your minimum order quantity?

A: Usually, our normal MOQ is 500 pcs, small quantity is available, please feel free to contact us for quote.

Q: What’s the product finishes you can offer?

A: Usually, we can make many finishes like brushing, anodizing, sandblasting, electroplating, painting, etching etc.

Q: Can I have a custom designed?

A: Certainly, We could provide design service according to customer’s instruction and our experience.

Q: What’s your main products?

A: Our main products are metal nameplate, nickel label and sticker, epoxy dome label, metal wine label etc.

Q: What’s the production capacity?

A: Our factory have large capacity, about 500,000 pieces each week.

Q: What’s the order process?

A: Firstly, samples should be approval before mass production.

We will arrange mass production after samples are approval, the payment should be received before shipping.

Q: What are the installation ways of your products?

A: Usually, the installation ways are double-sides adhesive,

Holes for screw or rivet, pillars on the back