Custom stainless steel engraved logo plate self-adhesive painting metal plaque

Product Description

| Product Name: | Custom stainless steel engraved logo plate self-adhesive painting metal plaque |

| Material : | Aluminum,stainless steel, Brass, copper, Bronze, etc. |

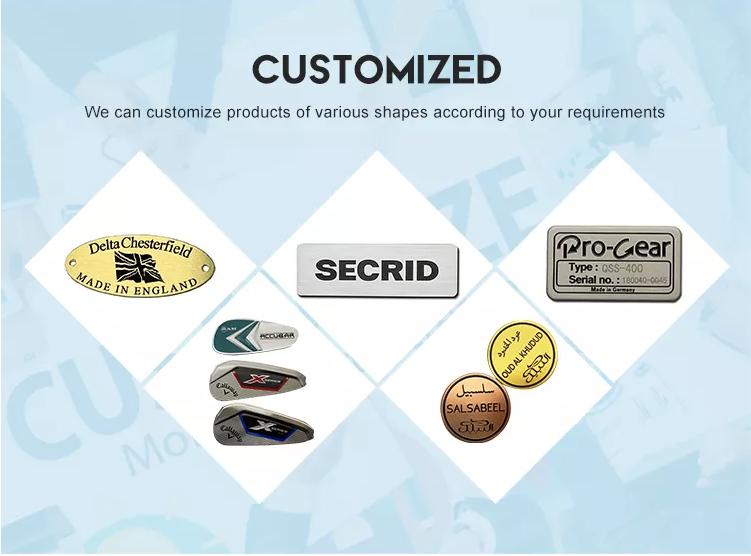

| Design : | Custom design, refer to final design artwork |

| Size & Color: | Customized |

| Shape : | Any shape for your selection or customized. |

| Artwork format: | Usually, PDF, AI, PSD, CDR, IGS etc file |

| MOQ : | Usually, Our MOQ is 500 pieces. |

| Application: | Machinery, equipment, furniture, elevator, motor, car, bike, household&Kitchen appliances, Gift box, Audio, industry products etc. |

| Sample time : | Usually, 5-7 working days. |

| Mass order time: | Usually, 10-15 working days. It depends on the quantity. |

| Finishes: | Engraving, Anodizing, painting, lacquering, brushing, diamond cutting, polishing, electroplating, enamel, printing, etching, die-casting, laser engraving, stamping, Hydraulic pressing etc. |

| Payment term: | Usually, our payment is T/T, Paypal, Trade Assurance order through Alibaba. |

Why Stainless Steel Label plates?

You can get stainless steel tags in a variety of thicknesses, with a smooth or brushed finish, depending on your company’s needs. Stainless steel is a robust and hard-wearing substrate, which means you can use it in indoor and outdoor environments. We can clearly mark important information such as etched serial numbers, instructions and regulatory codes onto its surface — and the nameplates can last for decades.

The finish is sleek and attractive, but durability is the biggest advantage of this material. It’s particularly well-suited to military and industrial applications, where the finish of serial numbers and display models looks crisp and easy to read. Stainless steel offer resistance to:

● Water

● Heat

● Corrosion

● Abrasion

● Chemicals

● Solvents

The state-of-the-art facilities here at Metal Marker mean we can perform an array of different processes and finishes depending on your company’s unique requirements. We can print your logo, message or designs onto practically any material, including stainless steel. Our cutting-edge printing and embossing techniques mean you can add appealing or practical finishing touches to metal tags.

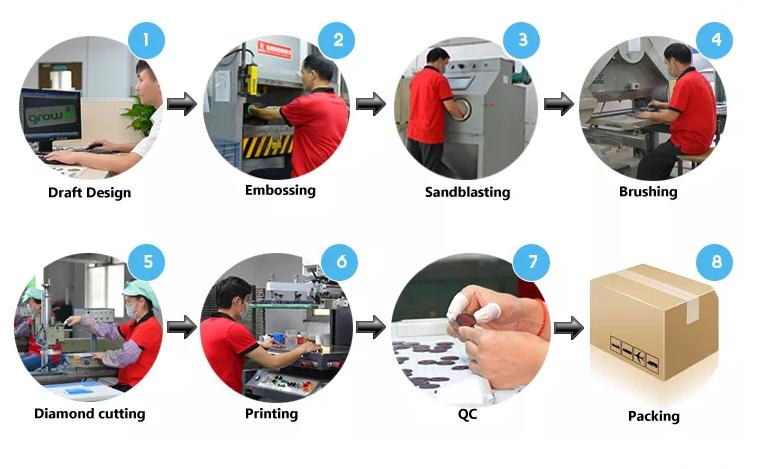

Processes

Below is a list of the various processes we can use to finish your stainless steel nameplates.

Engraving

Engraving involves leaving deep indents in the stainless steel to add text, numbers or a design onto the surface. A lot of time and attention is necessary to get this process just right because each letter is added individually, but the finish is impeccable.

Stamping

A faster, cheaper method of adding data or images to a metal tag is by using a single stamp and embedding the whole design at once. The text or data is imprinted on the surface of the stainless steel tag, and while it’s not as deep as engraving, the finished product won’t wear off.

Embossing

While engraving and stamping embed a design onto the surface, embossing creates raised designs that can withstand galvanizing, painting, acid cleaning, sandblasting and severe weather. Characters are added one at a time, so you can add variable and serialized data using this process.

Product Application

Related products

Product process

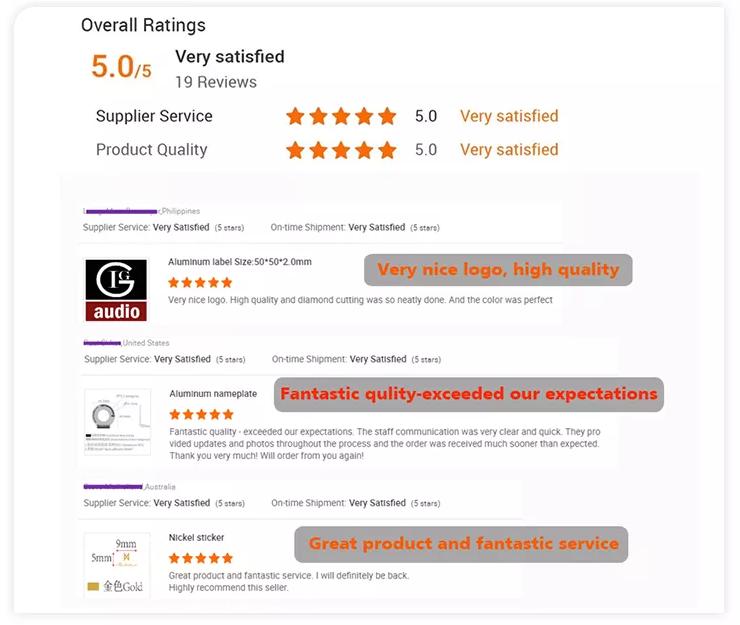

Customer Evaluation

FAQ

Q: How Can I get a quotation?

A: We will quote you exactly based on your information such as material, thickness, design drawing, size, quantity, specification etc.

Q: What are different payment methods?

A: Usually, T/T , Paypal, Credit card, Western union etc.

Q: What’s the order process?

A: Firstly, samples should be approval before mass production.

We will arrange mass production after samples are approval, the payment should be received before shipping.

Q: What’s the product finishes you can offer?

A: Usually, we can make many finishes like brushing, anodizing, sandblasting, electroplating, painting, etching etc.

Q: What’s your main products?

A: Our main products are metal nameplate, nickel label and sticker, epoxy dome label, metal wine label etc.

Q: What’s the production capacity?

A: Our factory have large capacity, about 500,000 pieces each week.

Q: How should you do the quality control?

A: We passed ISO9001, and the goods are 100% full inspected by QA before shipping.

Q: Are there any advanced machines in your factory?

A: Yes, we have so many advanced machines including 5 diamond cutting machines, 3 screen-printing machines,

2 big etching auto machines, 3 laser engraving machines, 15 punching machines , and 2 auto-color filling machines etc.

Q: What are the installation ways of your products?

A: Usually, the installation ways are double-sides adhesive,

Holes for screw or rivet, pillars on the back

Q: What’s the packing for your products?

A: Usually, PP bag, foam+ Carton, or according to customer’s packing instructions.