Metallic letters labels custom thin electroform nickel 3D logo transfer embossed decals metal stickers

Product Description

| Product Name: | Metallic letters labels custom thin electroform nickel 3D logo transfer embossed decals metal stickers |

| Material : | Nickel, Copper etc |

| Thickness : | Usually, 0.05-0.10mm or customized thickness |

| Size & Color: | Customized |

| Shape : | Any shape for your selection or customized. |

| Artwork format: | Usually, PDF, AI, PSD, CDR, IGS etc file |

| Shipping way : | By air or by express or by sea |

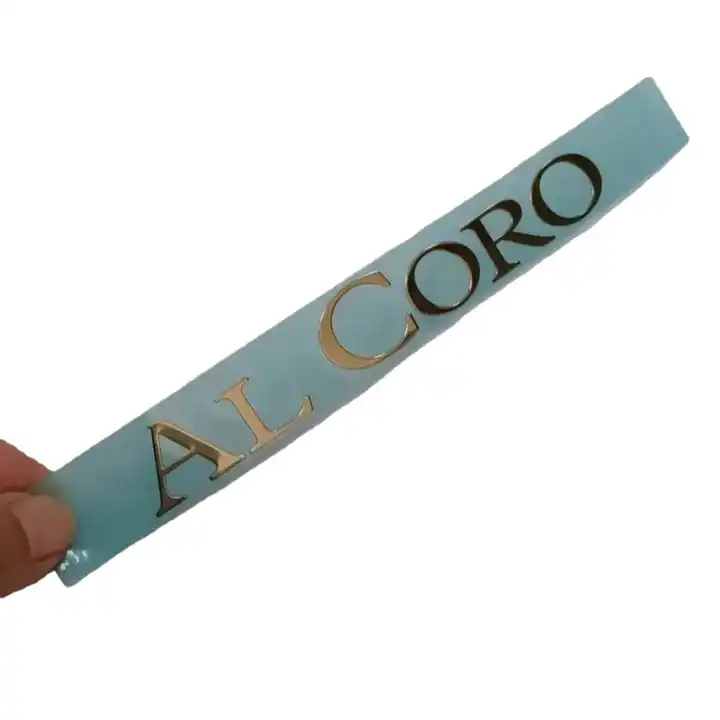

| Application: | Household appliances, mobile, car, camera, gift boxes, computer, sports equipment, leather, Wine bottle&Boxes , Cosmetics bottle etc. |

| Sample time : | Usually, 5-7 working days. |

| Production time: | Usually, 10-12 working days. It depends on the quantity. |

| Finishes: | Electroforming, painting, lacquering, brushing, polishing, electroplating, stamping |

| Payment term: | Usually, our payment is T/T, Paypal, Trade Assurance order through alibaba. |

Application

Production Process

FAQ

Q: How Can I get a quotation?

A: We will quote you exactly based on your information such as material, thickness, design drawing, size, quantity, specification etc.

Q: What are different payment methods?

A: Usually, T/T , Paypal, Credit card, Western union etc.

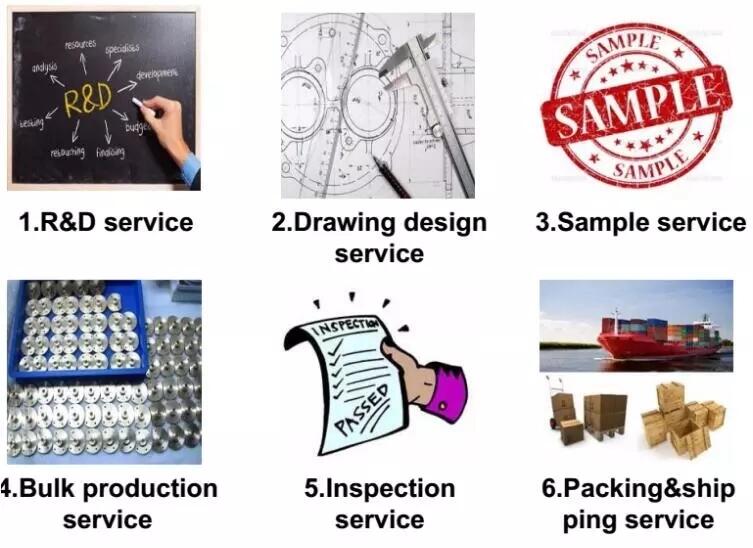

Q: What’s the order process?

A: Firstly, samples should be approval before mass production.

We will arrange mass production after samples are approval, the payment should be received before shipping.

Q: What’s the product finishes you can offer?

A: Usually, we can make many finishes like brushing, anodizing, sandblasting, electroplating, painting, etching etc.

Q: What’s your main products?

A: Our main products are metal nameplate, nickel label and sticker, epoxy dome label, metal wine label etc.

Q: What’s the production capacity?

A: Our factory have large capacity, about 500,000 pieces each week.

Q: How should you do the quality control?

A: We passed ISO9001, and the goods are 100% full inspected by QA before shipping.

Q: Are there any advanced machines in your factory?

A: Yes, we have so many advanced machines including 5 diamond cutting machines, 3 screen-printing machines,

2 big etching auto machines, 3 laser engraving machines, 15 punching machines , and 2 auto-color filling machines etc.

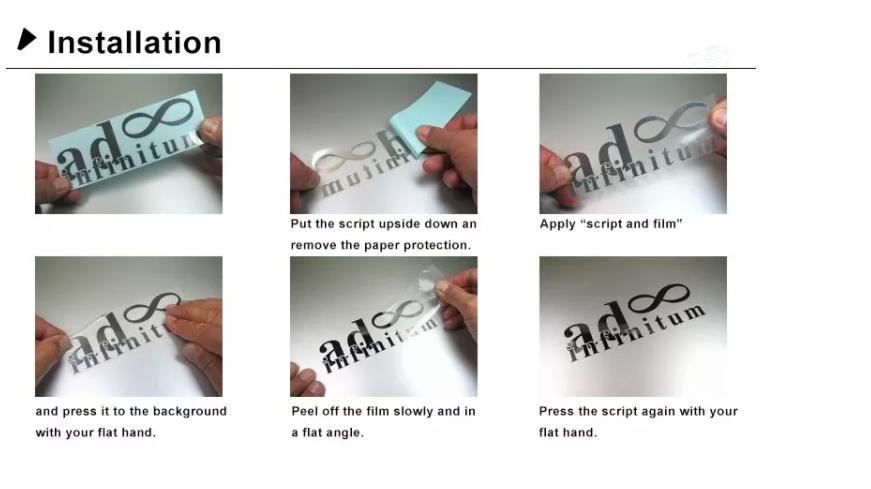

Q: What are the installation ways of your products?

A: Usually, the installation ways are double-sides adhesive,

Holes for screw or rivet, pillars on the back

Q: What’s the packing for your products?

A: Usually, PP bag, foam+ Carton, or according to customer’s packing instructions.