I. Clarify the Purpose of the Nameplate

- Identification Function: If it is used for equipment identification, it should include basic information such as the equipment name, model, and serial number. For example, on the production equipment in a factory, the nameplate can help workers quickly distinguish different types and batches of machines. For instance, on the nameplate of an injection molding machine, it may have content like "Injection Molding Machine Model: XX - 1000, Equipment Serial Number: 001", which is convenient for maintenance, repair, and management.

- Decorative Purpose: If it is used for decoration, such as on some high-end gifts and handicrafts, the design style of the nameplate should pay more attention to aesthetics and the coordination with the overall style of the product. For example, for a limited-edition metal handicraft, the nameplate may adopt retro fonts, exquisite carved borders, and use high-end colors like gold or silver to highlight the luxurious feel of the product.

- Warning Function: For equipment or areas with safety risks, the nameplate should focus on highlighting warning information. For example, on the nameplate of a high-voltage electrical box, there should be eye-catching words like "High Voltage Danger". The font color usually adopts warning colors such as red, and it may also be accompanied by danger sign patterns, such as lightning symbols, to ensure the safety of personnel.

II. Determine the Material of the Nameplate

- Metal Materials

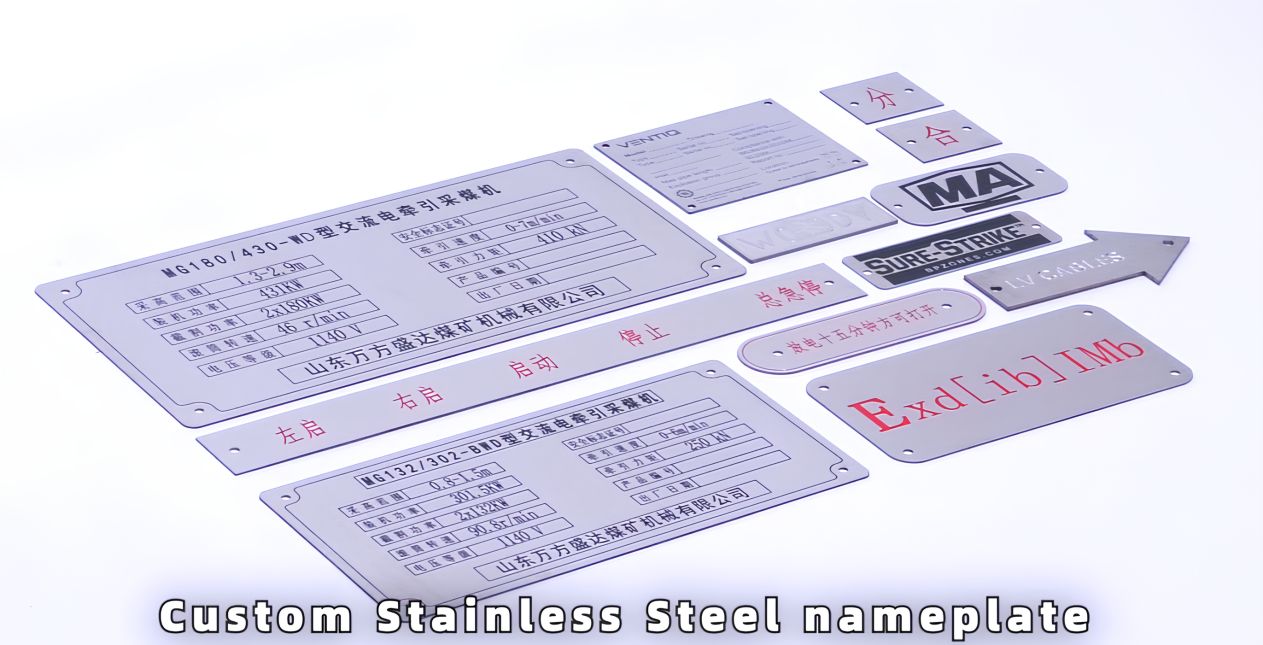

- Stainless Steel: This material has good corrosion resistance and is suitable for various harsh environments. For example, the nameplates of large outdoor mechanical equipment will not rust or be damaged easily even when exposed to wind, rain, sunlight, and other elements for a long time. Moreover, stainless steel nameplates can be made into exquisite patterns and texts through processes such as etching and stamping.

- Copper: Copper nameplates have a beautiful appearance and a good texture. They will develop a unique oxidized color over time, adding a quaint charm. They are often used on commemorative coins, high-end trophies, and other items that need to reflect quality and a sense of history.

- Aluminum: It is lightweight and relatively inexpensive, with good processing performance. It is widely used in products that are more cost-sensitive in mass production, such as the nameplates of some ordinary electrical equipment.

- Non-metal Materials

- Plastic: It has the characteristics of low cost and easy molding. It can be made through processes such as injection molding and silk-screen printing. For example, on some toy products, plastic nameplates can easily create various cartoon images and bright colors, and can also avoid causing harm to children.

- Acrylic: It has high transparency and a fashionable and bright appearance. It can be made into three-dimensional nameplates and is often used in store signs, indoor decorative nameplates, and other occasions. For example, the brand nameplate at the entrance of some fashion brand stores, made of acrylic material and illuminated by internal lights, can attract customers' attention.

III. Design the Content and Style of the Nameplate

- Content Layout

- Text Information: Ensure that the text is concise, clear, and the information is accurate. Arrange the font size and spacing reasonably according to the size and purpose of the nameplate. For example, on the nameplate of a small electronic product, the font should be small enough to accommodate all necessary information, but also ensure that it can be clearly recognized at a normal viewing distance. Meanwhile, pay attention to the correct grammar and spelling of the text.

- Graphic Elements: If graphic elements need to be added, ensure that they are coordinated with the text content and do not affect the reading of information. For example, in a company's logo nameplate, the size and position of the logo should be prominent but not cover other important information such as the company name and contact information.

- Style Design

- Shape Design: The shape of the nameplate can be a regular rectangle, circle, or a special shape customized according to the characteristics of the product. For example, the logo nameplate of a car brand may be designed into a unique outline according to the shape of the brand logo. For example, the nameplate in the shape of the Mercedes-Benz logo's three-pointed star can better highlight the brand characteristics.

- Color Matching: Choose an appropriate color scheme, considering that it matches the use environment and the color of the product itself. For example, the nameplates on medical equipment usually adopt colors that make people feel calm and clean, such as white and light blue; while on children's products, bright and lively colors such as pink and yellow are used.

IV. Choose the Production Process

- Etching Process: It is suitable for metal nameplates. Through the chemical etching method, fine patterns and texts can be made. This process can form evenly textured patterns and texts on the surface of the nameplate, giving them a three-dimensional effect. For example, when making the nameplates of some exquisite knives, the etching process can clearly present the brand logo, steel model, and other information of the knives, and can withstand a certain degree of wear.

- Stamping Process: Use molds to stamp metal sheets into shape. It can quickly and efficiently make a large number of nameplates of the same specification, and can also make nameplates with a certain thickness and texture. For example, many nameplates on car engines are made through the stamping process. Their characters are clear, the edges are neat, and they have high quality and stability.

- Printing Process: It is more suitable for nameplates made of plastic, paper, and other materials. It includes methods such as screen printing and digital printing. Screen printing can achieve large-area color printing with bright colors and strong covering power; digital printing is more suitable for making nameplates with complex patterns and rich color changes, such as some personalized custom gift nameplates.

- Carving Process: It can be used on materials such as wood and metal. Artistic nameplates can be made through manual carving or CNC carving. Manually carved nameplates are more personalized and have artistic value, such as the nameplates on some traditional handicrafts; CNC carving can ensure precision and efficiency and is suitable for mass production.

V. Consider the Installation Method

- Adhesive Installation: Use glue or double-sided tape to stick the nameplate on the surface of the product. This method is simple and convenient and is suitable for some products that are light in weight and have a flat surface. However, it is necessary to choose an appropriate adhesive to ensure that the nameplate is firmly adhered and will not fall off during long-term use. For example, on some electronic products with plastic shells, strong double-sided tape can be used to stick the nameplate well.

- Screw Fixing: For nameplates that are heavy and need to be disassembled and maintained frequently, the screw fixing method can be adopted. Pre-drill holes on the nameplate and the surface of the product, and then install the nameplate with screws. This method is relatively firm, but it may cause certain damage to the surface of the product. Attention should be paid to protecting the appearance of the product during installation. For example, the nameplates of some large mechanical equipment usually adopt this installation method.

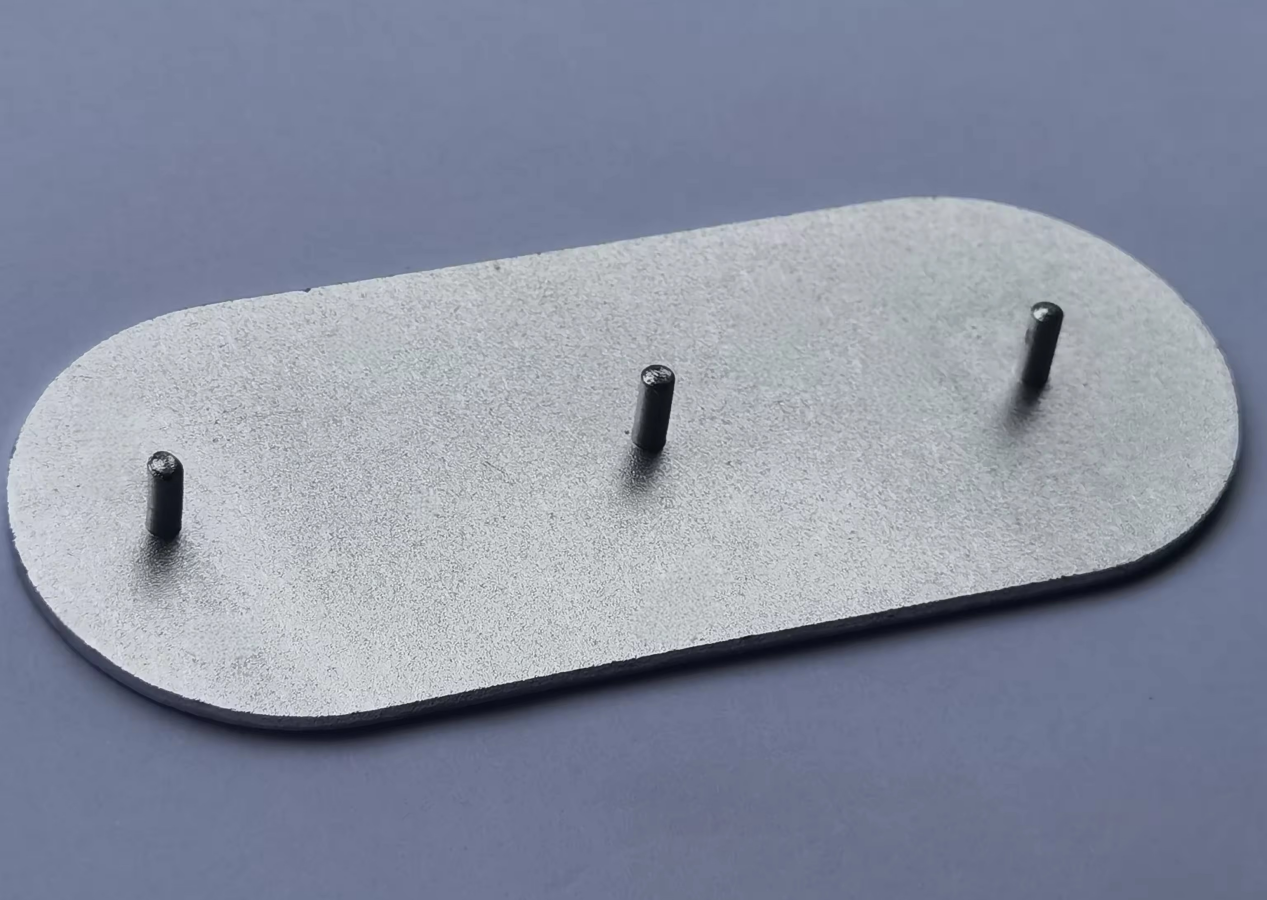

- Riveting: Use rivets to fix the nameplate on the product. This method can provide good connection strength and has a certain decorative effect. It is often used on metal products. For example, the nameplate on some metal toolboxes is installed by riveting, which is both firm and beautiful.

Welcome to quote for your projects:

Contact: info@szhaixinda.com

Whatsapp/phone/Wechat : +86 15112398379

Post time: Jan-13-2025