(一)Electroplating Process

Visual Effects

Electroplating is the deposition of a metal coating on a metal surface through electrolysis. Nickel plating can give the nameplate a silvery - white and bright luster, with extremely high gloss, enhancing the overall texture of the product and giving people a delicate and high - end visual experience. Chrome plating can make the nameplate surface even more shiny and eye - catching, with strong reflectivity, and is often used for nameplates of high - end products that pursue extreme appearances. Moreover, different colored coatings can be achieved through electroplating. For example, imitation gold electroplating can make the nameplate present a golden appearance, meeting the needs of specific design styles.

Durability

The electroplated layer can effectively improve the corrosion resistance of the nameplate. Taking nickel plating as an example, the nickel layer can isolate the metal substrate from corrosive substances in the external environment, such as moisture, oxygen, and chemical substances, thus slowing down the oxidation and corrosion rate of the metal. The chrome - plated layer not only has high hardness but also has good wear resistance, being able to effectively resist scratches and abrasions during daily use and extending the service life of the nameplate.

(二)Anodizing Process

Visual Effects

Anodizing is mainly applied to nameplates made of aluminum and aluminum - alloy materials. During the anodizing process, a porous oxide film is formed on the aluminum surface. By dyeing the oxide film, a wide variety of colors can be obtained, ranging from bright pure colors to soft gradient colors, with high color stability and resistance to fading. In addition, the surface texture after anodizing is unique. Depending on the process, it can present a matte or semi - matte effect, giving people a delicate and high - end visual experience.

Durability

The oxide film formed by anodizing has high hardness and wear resistance, which can effectively protect the metal substrate from wear. At the same time, the chemical stability of the oxide film is strong, greatly improving the corrosion resistance of the nameplate, enabling it to maintain good performance under harsh environmental conditions.

(三)Painting Process

Visual Effects

Painting can provide almost any color choice for nameplates. Whether it is a bright color or a calm tone, it can be achieved through painting. Moreover, according to different paint materials and processes, different gloss effects can be obtained. For example, high - gloss paint can make the nameplate surface shine brightly, while matte paint endows the nameplate with a low - key and soft texture. In addition, special texture effects such as frosted and crack patterns can be achieved through painting, increasing the uniqueness and decorative nature of the nameplate.

Durability

High - quality paint can form a strong protective film on the nameplate surface, effectively isolating external moisture, oxygen, and chemical substances, preventing the metal from rusting and corroding. At the same time, the paint layer also has a certain degree of wear resistance, being able to resist slight scratches and collisions and protect the patterns and text information on the nameplate from being damaged.

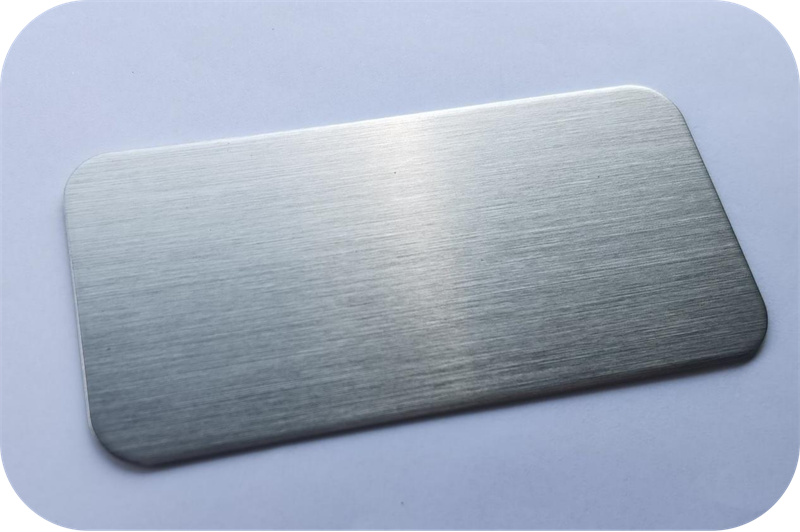

(四)Brushed Process

Visual Effects

The Brushed process forms uniform filamentous textures on the metal surface through mechanical friction. This texture endows the nameplate with a unique texture, presenting a delicate and soft metallic luster. Compared with a smooth surface, the Brushed effect has more layers and three - dimensionality, giving people a simple and fashionable visual experience, especially suitable for nameplates of products that pursue a simple style.

Durability

Although the Brushed process has a relatively small effect on improving the corrosion resistance of the nameplate, it can, to a certain extent, cover up the fine flaws and scratches on the metal surface, reducing the corrosion risk caused by surface flaws. At the same time, the surface hardness after Brushed increases slightly, being able to resist slight daily wear to a certain extent.

In conclusion, different surface treatment processes have their own unique influences on the visual effects and durability in nameplate customization. In the actual nameplate customization process, it is necessary to comprehensively select appropriate surface treatment processes according to the product positioning, usage environment, and design requirements to achieve the best appearance effects and durability.

Welcome to quote for your projects:

Contact: info@szhaixinda.com

Whatsapp/phone/Wechat : +86 15112398379

Post time: Feb-21-2025