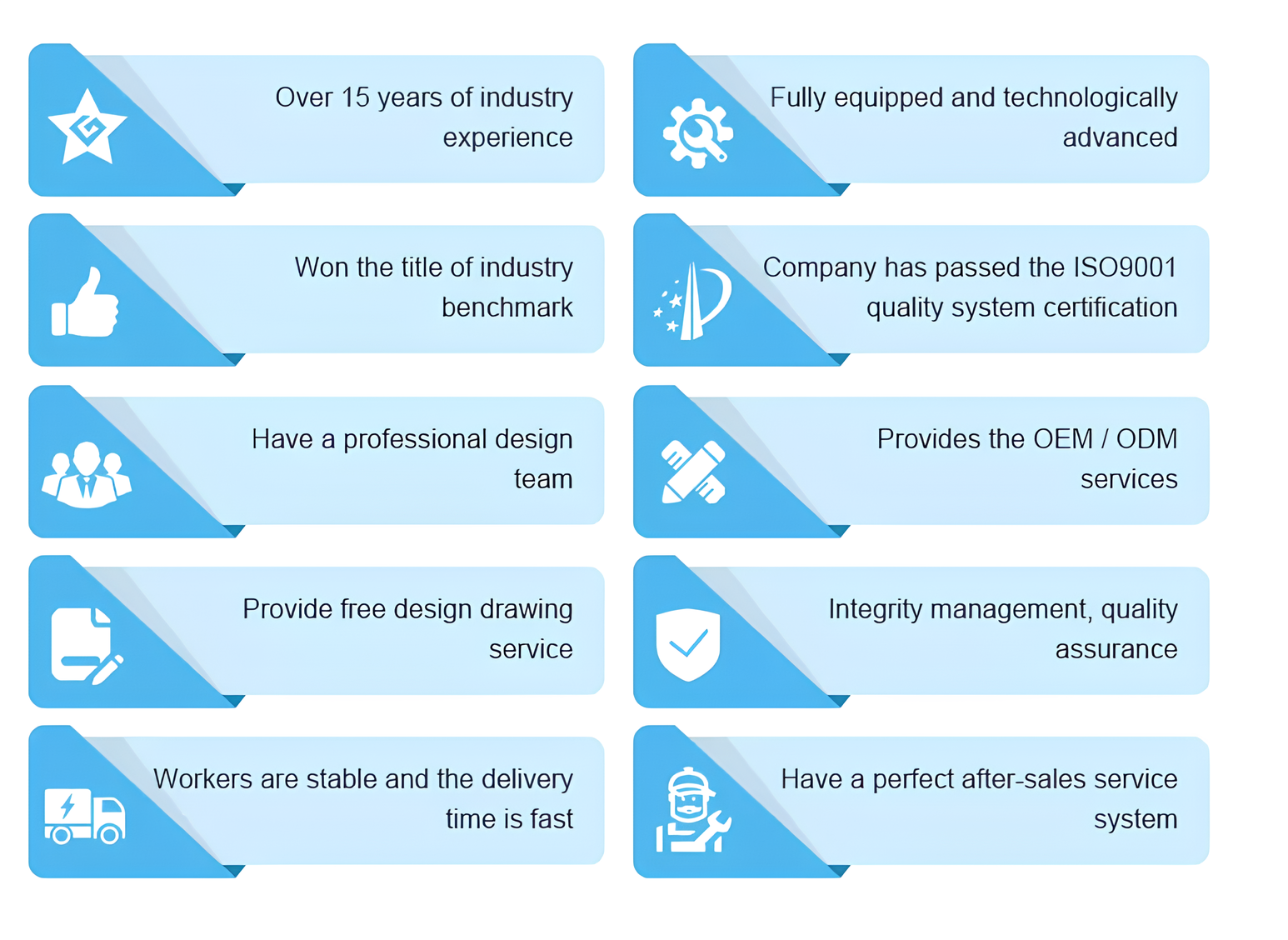

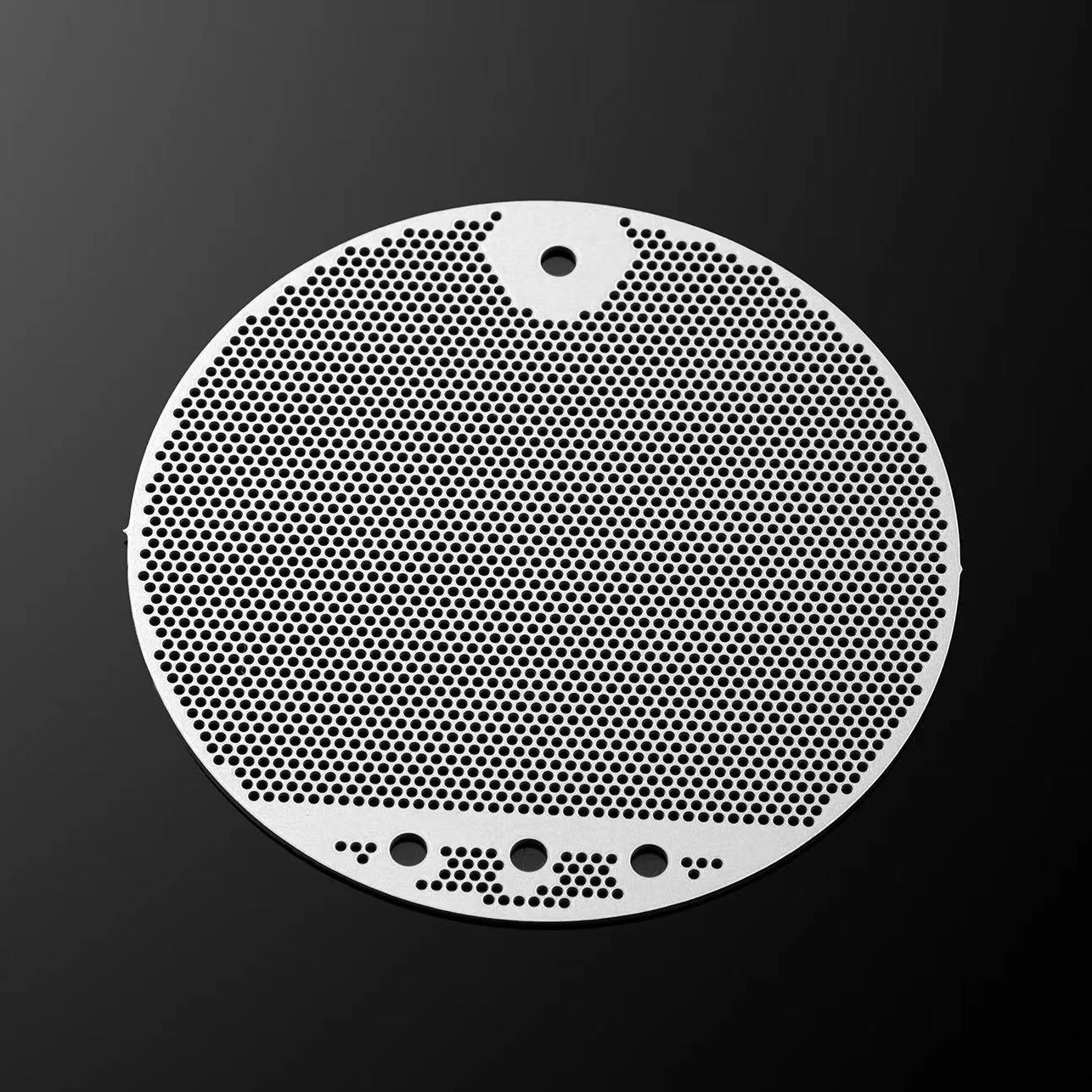

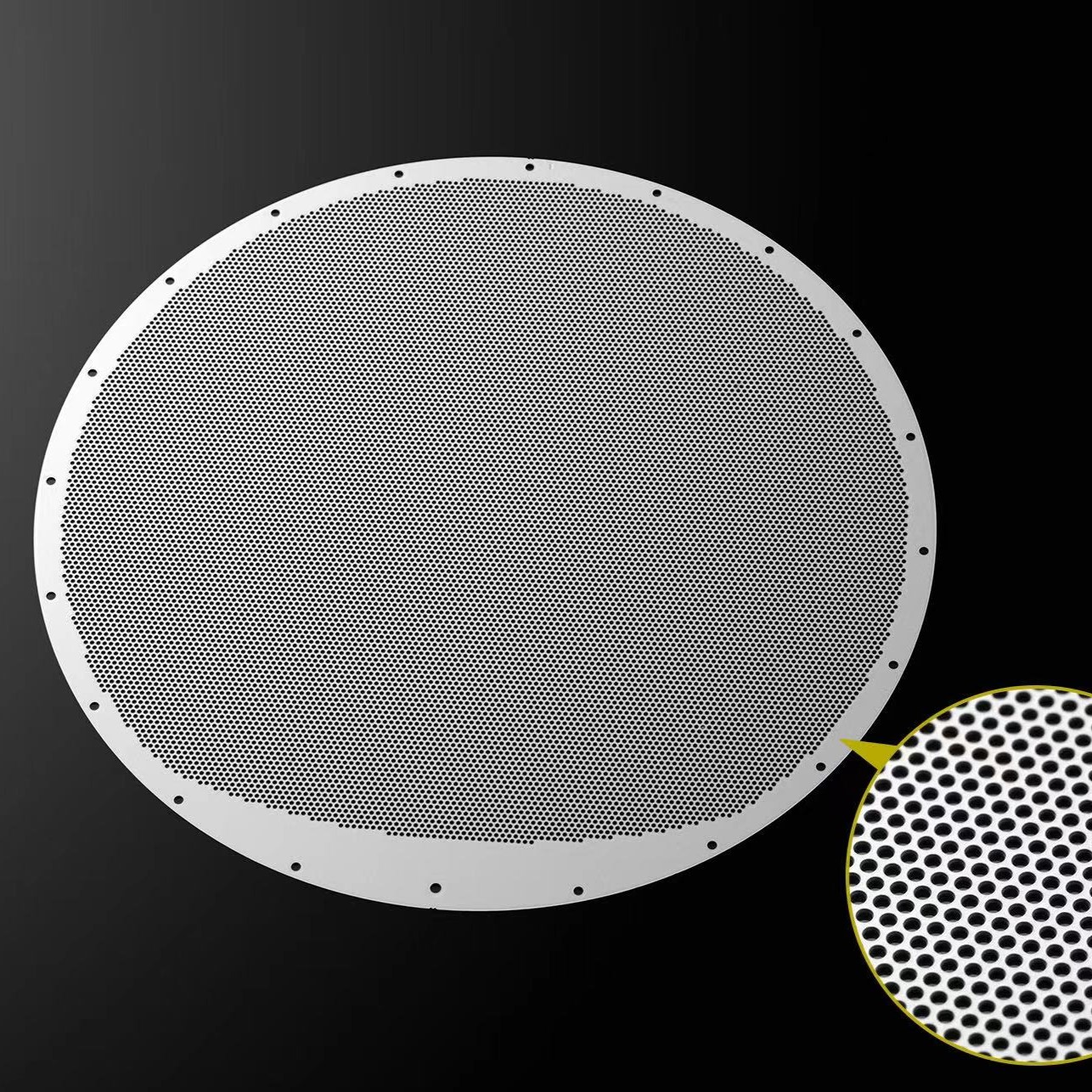

Precision Etched Stainless Steel Filter / Audio Speaker Metal Protective Cover Mesh

Product Description

| Product Name: | Precision Etched Stainless Steel Filter / Audio Speaker Metal Protective Cover Mesh |

| Material : | Stainless steel,aluminum,brass, copper, bronze, iron, precious metals or customize |

| Design : | Custom design, refer to final design artwork |

| Size & Color: | Customized |

| Thickness : | 0.03-2mm is available |

| Shape: | Hexagon, oval, round, rectangle, square, or customized |

| Features | No burrs,No broken point,no plugging holes |

| Application: | Car speaker mesh, Fiber filter,Textile machines or customize |

| Sample time : | Usually, 5-7 working days. |

| Mass order time: | Usually, 10-15 working days. It depends on the quantity. |

| Main process: | Stamping,Chemical etching,Laser cutting etc. |

| Payment term: | Usually, our payment is T/T, Paypal, Trade Assurance order through Alibaba. |

Product Application

Photo-Etching: Ideal for Car Loudspeaker Grilles

Photo-etching has been widely used in the manufacturing of car loudspeaker mesh grilles, many branding car manufacturers or loudspeaker manufacturer benefit from this technology, as it features:

1.Low tooling cost.no need for expensive DIE/Mould -- prototype normally costs only hundred dollars

2.Design flexibility -- Photo etching allows much flexibility on product design no matter it is product outer shape or the hole patterns, there is even no cost for complex designs.

3.Stress and burr free, smooth surface -- the material temper will not be affected during this process and it can guarantee a very smooth surface

4. Easy to coordinate with other manufacturing processes such as PVD plating, stamping, brushing, polishing and so on

5.Various material options -- stainless steel, copper, brass, aluminum, titanium, metal alloy at the thickness from 0.02mm to 2mm are all available.

Company profile

FAQ:

Q: What’s your main products?

A: Our main products are metal nameplate, nickel label and sticker, epoxy dome label, metal wine label etc.

Q: What’s the production capacity?

A: Our factory have large capacity, about 500,000 pieces each week.

Q: How should you do the quality control?

A: We passed ISO9001, and the goods are 100% full inspected by QA before shipping.

Q: Are there any advanced machines in your factory?

A: Yes, we have so many advanced machines including 5 diamond cutting machines, 3 screen-printing machines,

2 big etching auto machines, 3 laser engraving machines, 15 punching machines , and 2 auto-color filling machines etc.

Q: What are the installation ways of your products?

A: Usually, the installation ways are double-sides adhesive,

Holes for screw or rivet, pillars on the back

Q: What’s the packing for your products?

A: Usually, PP bag, foam+ Carton, or according to customer’s packing instructions.