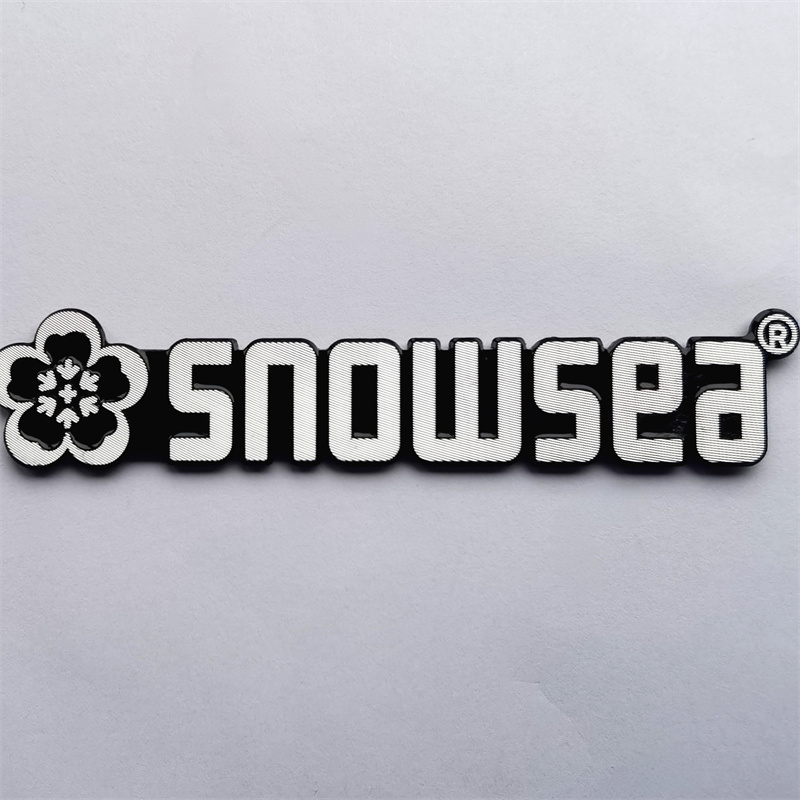

Custom Color Small Size High-Gloss 3D Logo Self-Adhesive Aluminum Metal Label

Product Description

| Product Name: | Custom Color Small Size High-Gloss 3D Logo Self-Adhesive Aluminum Metal Label |

| Material : | Aluminum,stainless steel, Brass, copper, Bronze, iron etc. |

| Design : | Custom design, refer to final design artwork |

| Size & Color: | Customized |

| Shape : | Any shape for your selection or customized. |

| Artwork format: | Usually, PDF, AI, PSD, CDR, IGS etc file |

| MOQ : | Usually, Our MOQ is 500 pieces. |

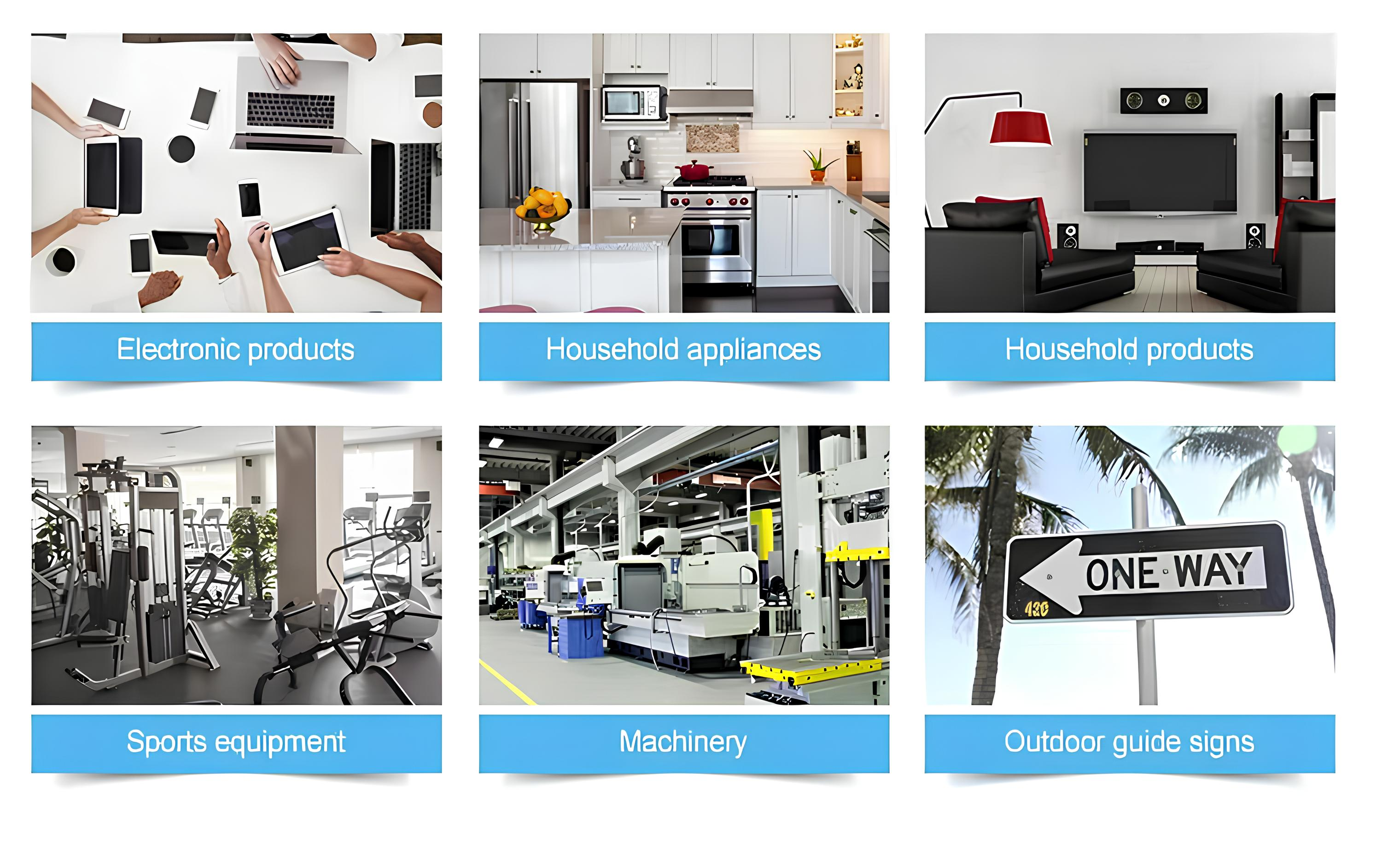

| Application: | Furniture, Machinery, equipment, elevator, motor, car, bike, household&Kitchen appliances, Gift box, Audio, industry products etc. |

| Sample time : | Usually, 5-7 working days. |

| Mass order time: | Usually, 10-15 working days. It depends on the quantity. |

| Finishes: | Engraving, Anodizing, painting, lacquering, brushing, diamond cutting, polishing, electroplating, enamel, printing, etching, die-casting, laser engraving, stamping, Hydraulic pressing etc. |

| Payment term: | Usually, our payment is T/T, Paypal, Trade Assurance order through Alibaba. |

Product Application

Introduction to the Diamond-Cut Process

I. Process Overview and Principle

The Diamond-Cut process is a unique way of treating the surface of materials. In order to achieve high-gloss textures and effects. It works by using special cutting tools to carve and cut on the surface of the material. Through the relative movement between the tool and the material, patterns and textures are formed by removing part of the material according to a preset path and depth.

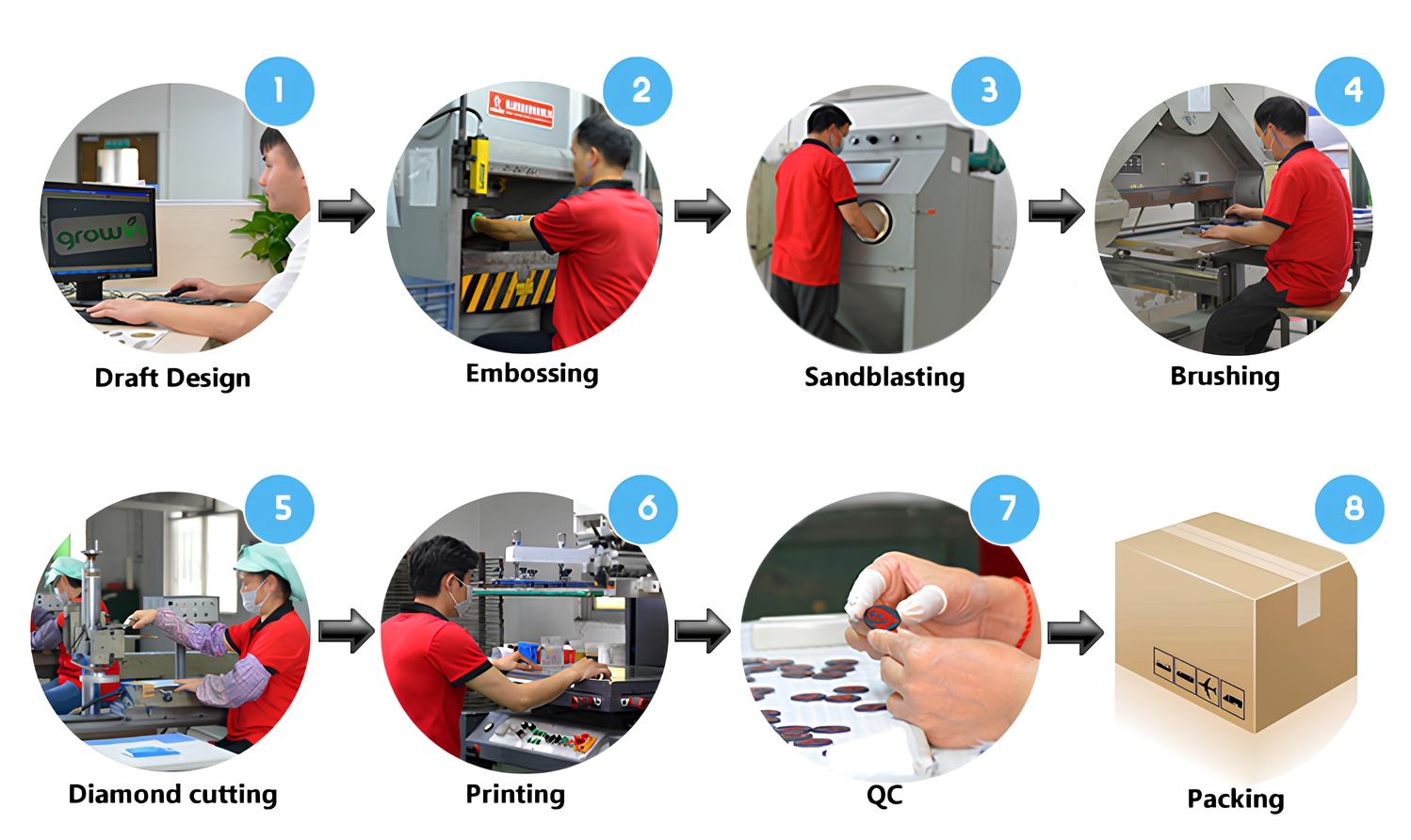

II.Process Flow

The process flow includes designing patterns while considering the characteristics and feasibility of the material, preparing the material by pretreating it to make the surface flat, clamping and positioning, doing the Diamond-Cut processing while controlling the parameters, checking the quality to make sure the patterns are complete and the lines are clear, and doing post-processing to improve the aesthetics and corrosion resistance.

III. Process Characteristics and Applications

This process has strong decorative power. It's very precise and has a wide range of applications. It's widely used in industries such as jewelry, watches, electronics, and gift crafts to make products more unique and artistic.

Product process

FAQ:

Q: What’s the production capacity?

A: Our factory have large capacity, about 500,000 pieces each week.

Q: How should you do the quality control?

A: We passed ISO9001, and the goods are 100% full inspected by QA before shipping.

Q: Are there any advanced machines in your factory?

A: Yes, we have so many advanced machines including 5 diamond cutting machines, 3 screen-printing machines,

2 big etching auto machines, 3 laser engraving machines, 15 punching machines , and 2 auto-color filling machines etc.

Q: What are the installation ways of your products?

A: Usually, the installation ways are double-sides adhesive,

Holes for screw or rivet, pillars on the back

Q: What’s the packing for your products?

A: Usually, PP bag, foam+ Carton, or according to customer’s packing instructions.